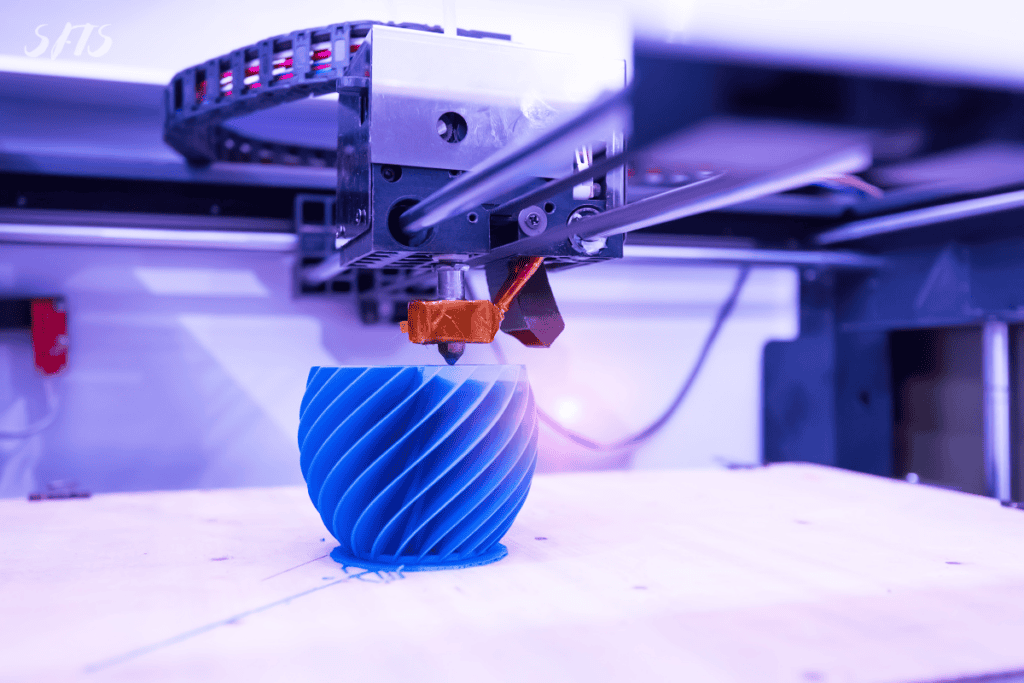

3D printing, also known as additive manufacturing, is a revolutionary technology that has transformed various industries, including jewelry making. It involves the creation of three-dimensional objects by layering materials based on a digital design. In the context of jewelry making, 3D printing allows designers to bring their intricate and complex designs to life with precision and accuracy.

Traditionally, jewelry making involved a labor-intensive process that required skilled craftsmen to meticulously carve and shape metals and gemstones. However, with the advent of 3D printing technology, the jewelry industry has experienced a significant shift in how jewelry is designed and produced. This article will explore the advantages of 3D printing in jewelry design and production, its impact on the industry, the role of CAD software, material selection, challenges, and the intersection of technology and art in 3D printed jewelry.

The Advantages of 3D Printing in Jewelry Design and Production

One of the key advantages of 3D printing in jewelry design is increased design flexibility. With traditional methods, designers were limited by the constraints of manual craftsmanship. However, with 3D printing, designers can create intricate and complex designs that were previously impossible to achieve. This opens up a world of possibilities for creativity and innovation in jewelry design.

Another advantage is faster production times. Traditional jewelry making methods can be time-consuming, especially for complex designs. With 3D printing, once the digital design is finalized, the production process can be automated, significantly reducing the time required to produce a piece of jewelry. This allows designers to bring their creations to market more quickly and efficiently.

Furthermore, 3D printing reduces waste and cost. Traditional manufacturing methods often result in a significant amount of material waste due to the need for manual shaping and carving. In contrast, 3D printing only uses the necessary amount of material, minimizing waste. Additionally, the cost of producing jewelry through 3D printing can be lower compared to traditional methods, as it eliminates the need for expensive molds and tooling.

Lastly, 3D printing offers improved accuracy and precision. With traditional methods, there is always a margin of error in the manual crafting process. However, 3D printing allows for precise replication of designs, ensuring that each piece of jewelry is consistent and accurate. This level of precision is particularly important for intricate designs and custom-made jewelry.

The Impact of 3D Printing on the Jewelry Industry

The introduction of 3D printing technology has disrupted traditional manufacturing methods in the jewelry industry. It has democratized the industry by increasing accessibility for small businesses and independent designers. In the past, large jewelry manufacturers had a monopoly on the market due to their access to expensive machinery and resources.

However, with 3D printing, small businesses and independent designers can now compete on a level playing field, as they can create high-quality jewelry without the need for significant upfront investment.

Additionally, 3D printing has expanded design possibilities in the jewelry industry. Designers are no longer limited by the constraints of traditional manufacturing methods. They can now experiment with intricate and complex designs that were previously impossible to achieve. This has led to a surge in innovative and unique jewelry designs that push the boundaries of traditional aesthetics.

How 3D Printing is Changing the Face of Custom Jewelry

Custom jewelry has always been highly sought after, as it allows individuals to express their unique style and personality. However, traditional methods of custom jewelry production were often time-consuming and costly. With 3D printing, custom jewelry production has become more efficient and accessible.

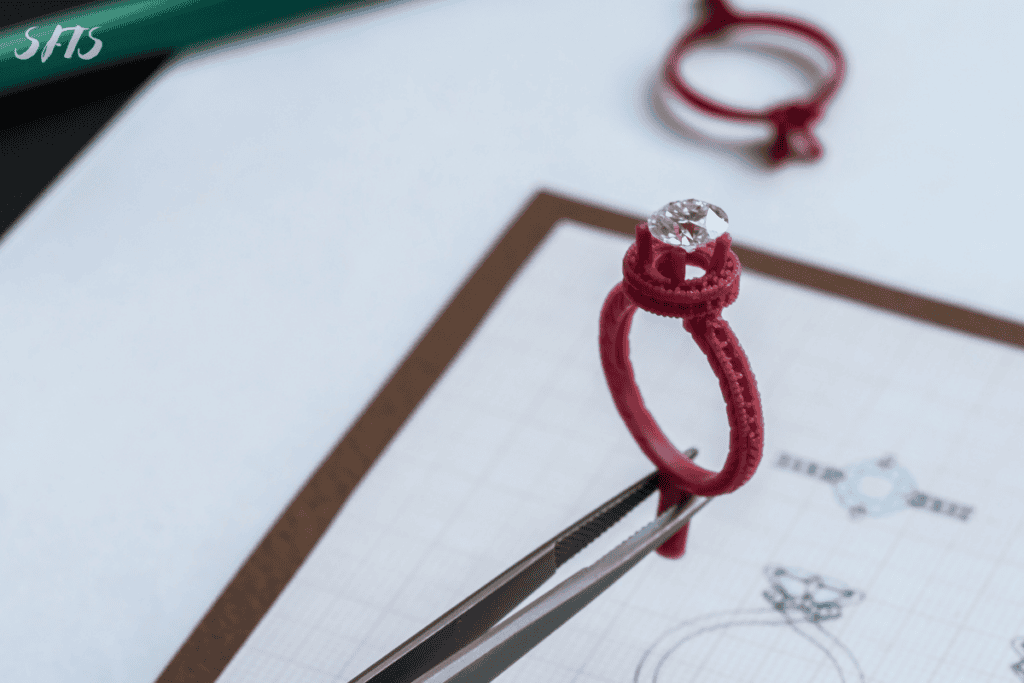

One of the key advantages of 3D printing in custom jewelry is the ability to create one-of-a-kind pieces. Traditional methods often required manual crafting, which made it difficult to replicate intricate designs accurately. With 3D printing, designers can create highly detailed and unique pieces that are tailored to the individual’s preferences.

Furthermore, 3D printing offers personalization options for customers. Through the use of CAD software, customers can customize their jewelry by choosing different materials, gemstones, and design elements. This level of personalization was previously only available to a select few due to the high cost and time required for manual customization.

Lastly, 3D printing has increased efficiency in custom jewelry production. With traditional methods, custom jewelry often required multiple iterations and adjustments, which could be time-consuming and costly. However, with 3D printing, designers can quickly iterate and make adjustments to the digital design before producing the final piece. This reduces the time and cost associated with custom jewelry production.

The Role of CAD Software in 3D Printing Jewelry

CAD (Computer-Aided Design) software plays a crucial role in 3D printing jewelry. It allows designers to create digital models of their jewelry designs, which can then be translated into physical objects through 3D printing.

CAD software enables designers to visualize their ideas and make precise adjustments to their designs. It offers a range of tools and features that allow designers to manipulate shapes, sizes, and proportions with ease. This level of control is essential for creating intricate and complex jewelry designs.

There are several popular CAD software programs used in jewelry design. One example is RhinoGold, which is specifically designed for jewelry design and offers a wide range of tools and features tailored to the industry’s needs. Another popular CAD software is Matrix, which is known for its intuitive interface and powerful modeling capabilities. These software programs provide designers with the tools they need to bring their creative visions to life.

The Importance of Material Selection in 3D Printed Jewelry

Material selection is a critical aspect of 3D printed jewelry production. The choice of material can significantly impact the final product’s aesthetics, durability, and cost.

There are various materials used in 3D printed jewelry, including precious metals such as gold, silver, and platinum, as well as non-precious metals like stainless steel and titanium. Each material has its unique properties and characteristics that need to be considered when selecting the appropriate material for a specific design.

Factors to consider when selecting materials include the desired aesthetics, durability, weight, and cost. For example, gold is a popular choice for its luxurious appearance and durability. However, it is also more expensive compared to other materials. On the other hand, stainless steel is a more affordable option but may not have the same level of luxury as gold.

The impact of material selection on the final product goes beyond aesthetics. It also affects the durability and wearability of the jewelry. For example, certain materials may be more prone to scratching or tarnishing over time. Therefore, it is essential to consider the intended use and longevity of the jewelry when selecting materials.

The Future of 3D Printing in Jewelry Making

The future of 3D printing in jewelry making holds great potential for further advancements in technology. As the technology continues to evolve, we can expect improvements in speed, resolution, and material options. This will further enhance the design possibilities and quality of 3D printed jewelry.

One potential advancement is the use of multi-material 3D printing. Currently, most 3D printers can only print with a single material at a time. However, researchers are working on developing printers that can print with multiple materials simultaneously. This would allow for even more intricate and complex designs by combining different materials with varying properties.

Another area of potential advancement is the use of biocompatible materials for 3D printed jewelry. Biocompatible materials are safe to wear on the skin and can be used for medical applications such as implants. The development of biocompatible materials for 3D printed jewelry would open up new possibilities for wearable technology and personalized medical jewelry.

Furthermore, advancements in 3D scanning technology could revolutionize the custom jewelry industry. Currently, custom jewelry often requires manual measurements and adjustments. However, with the development of more accurate and accessible 3D scanning technology, customers could simply scan their body or specific body parts to create custom-fit jewelry.

The Challenges of 3D Printing in Jewelry Manufacturing

While 3D printing offers numerous advantages in jewelry manufacturing, it also presents several challenges that need to be addressed.

One of the technical challenges in the printing process is achieving a high level of detail and resolution. Some designs may require intricate details that can be challenging to reproduce accurately with 3D printing. Additionally, achieving a smooth surface finish can be difficult, especially with certain materials. These technical challenges require ongoing research and development to improve the quality and resolution of 3D printed jewelry.

Quality control is another challenge in 3D printed jewelry manufacturing. As with any manufacturing process, there is always a risk of defects or errors. It is crucial to have robust quality control measures in place to ensure that each piece of jewelry meets the desired standards of quality and accuracy.

Cost considerations are also important when it comes to 3D printing in jewelry manufacturing. While the cost of 3D printing has decreased over the years, it can still be more expensive compared to traditional manufacturing methods for certain designs or materials. It is essential to carefully evaluate the cost-benefit analysis when deciding whether to use 3D printing for a particular piece of jewelry.

The Role of Skilled Craftsmanship in 3D Printed Jewelry

Despite the advancements in technology, skilled craftsmanship still plays a vital role in the production of high-quality 3D printed jewelry. While 3D printing allows for precise replication of designs, it is the skilled artisans who bring the final touches and polish to the jewelry.

Skilled craftsmen are responsible for post-processing the 3D printed jewelry, which involves removing support structures, polishing the surface, and setting gemstones. Their expertise and attention to detail ensure that each piece of jewelry meets the desired standards of quality and aesthetics.

Furthermore, skilled craftsmen can work hand in hand with designers to push the boundaries of what is possible with 3D printing. They can provide valuable insights and feedback on the design and production process, leading to further improvements in the quality and innovation of 3D printed jewelry.

The Intersection of Technology and Art in 3D Printed Jewelry

The intersection of technology and art is at the heart of 3D printed jewelry. It combines the precision and accuracy of technology with the creativity and artistic vision of designers.

Technology provides designers with the tools and capabilities to create intricate and complex designs that were previously impossible to achieve. It allows for precise replication of designs, ensuring consistency and accuracy in each piece of jewelry. Furthermore, technology enables designers to experiment with new materials, textures, and forms, pushing the boundaries of traditional aesthetics.

Artistic vision is equally important in 3D printed jewelry. Designers bring their creativity and unique perspectives to create jewelry that tells a story or evokes emotions. They use technology as a tool to bring their artistic vision to life, resulting in innovative and unique designs that blend technology and art seamlessly.

The Art of Precision in 3D Printed Jewelry Making

In conclusion, 3D printing has revolutionized the jewelry industry by offering increased design flexibility, faster production times, reduced waste and cost, and improved accuracy and precision. It has disrupted traditional manufacturing methods, making the industry more accessible for small businesses and independent designers. Furthermore, 3D printing has expanded design possibilities and transformed the custom jewelry market.

CAD software plays a crucial role in 3D printing jewelry, allowing designers to create digital models of their designs. Material selection is also important, as it impacts the final product’s aesthetics, durability, and cost. The future of 3D printing in jewelry making holds great potential for further advancements in technology, such as multi-material printing and the use of biocompatible materials.

While 3D printing offers numerous advantages, it also presents challenges in terms of technical limitations, quality control, and cost considerations. Skilled craftsmanship remains essential in the production of high-quality 3D printed jewelry, working hand in hand with technology to bring the final touches and polish to the jewelry.

The intersection of technology and art is at the heart of 3D printed jewelry, combining precision and creativity to create innovative and unique designs.

Leave a Reply